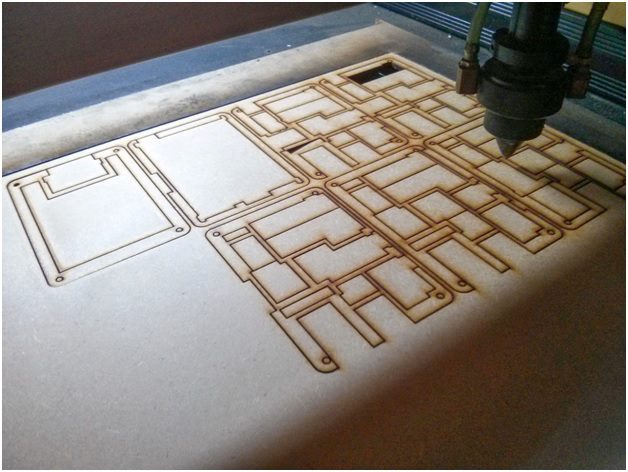

Laser cutters are manufacturing tools used in prototypes. Artists, designers, and engineers often use them to etch designs into blocks of metals or flat materials. These are usually thin and piercing because they are meant to engrave and cut into flat materials.

They use a focused beam of light to cut the patterns, materials, and geometries designed by manufacturers and business owners for their products’ prototypes. Aside from the primary goal of cutting, the lasers can also etch or raster the work pieces by heating the surfaces of the materials that they are working with. With the top layers peeled off, it can change into something where a raster operation can be easily made.

The cutters are convenient tools in the manufacturing and prototyping industries. You can get more information about them on sites like https://aeonlaser.ca and see other software and training to help you get more done with less.

Many artists and lasers use them as fabrication tools to create their digital designs and make them tangible. Similar technology is utilized through the use of a cnc plasma table canada (or elsewhere more relevant), the main difference being that plasma cutters are used on conductive materials, this is due to the electronically conductive gas used in plasma cutters, which is a more affordable option when accurately cutting metal or other similar materials.

What are Laser Cutters?

A metal laser cutting machine is one of the tools used in computer numerical controlled or CNC machines relevant to prototyping and designing device parts. The bulk of the work is often controlled by a computer where the designer often puts the software’s patterns. The cutters will then do the cuts as they were specified, and they will etch something in the materials.

Generally, a cutting bed is an area where the materials are placed. Many of the lasers are all-around tools because they can make many patterns in less than an hour. They can be used in anything, including rastered artworks or cardboard prototypes. Common ones are used for making a dent on paper, plastics, and cardboard. The powerful varieties are often used for thicker materials like metals.

These tools are very quick, and they are often ideal for products that are meant to be mass-produced. They can churn out the design parts in the space of a few minutes. They are similar to the work of 3D printers, where rapid prototypes are needed to start mass production and to have cheaper costs. You can read more about 3D printing on this site here.

Working with the Cuts

A few different types of cutters are available in the market, but they often utilize the same process for cutting the materials. They originate from resonators where the lights are sent out of beams. The intensity of the lights is reflected through systematically-placed mirrors, and they go out of the head. They are narrowed down in a thin beam that contains concentrated light.

This is a beam that’s often used for rastering raw stock. The head of the laser is usually mounted to a mechanical system called an XY gantry. This is a mechanical system that’s being run by chains or belts for more precise movements.

The gantry is the part that allows the edges of the laser to move forwards and backwards to make precision cuts according to the design on the computer software. For the lasers to penetrate a material, the bed’s block is focused on the focal point of the lens. This is where the light will be at its finest and focusing is needed for the tools to make an incision.

The difference between the various types of lasers comes from the types that the machines utilize. Types often depend on the thickness that these tools can cut because they have many power ranges. Generally, the high-powered ones are used on a more extensive and industrial scale for broader sections of metal sheets or plastics. The low-powered ones are used for more flammable materials like card stock, plastic wood, and paper.

Types to Know About

The three main types of cutters are neodymium, fiber, and CO2 lasers. Although they may be built similarly, they have the distinctions that make them different in their way. Some of them may differ in their range of power, the kind of material they can penetrate, and the sheets’ thickness that they can cut. You can know more about them with the following information:

CO2: This variety is generated from gas mixtures that were electrically-stimulated. They are the most common types out there because they are cost-effective solutions for many companies, requiring low power to operate. These can cut through various materials like acrylic, cardboard, foams, plastics, and anodized metals.

Neodymium: Doped crystals formed the neodymium and were in similar wavelengths with the CO2 varieties. This means that they are also cost-effective, but they have higher intensities. They can cut into thicker materials, but they may require higher power as well. They tend to experience wear and tear in just a few years, and they may need replacement after some time. They are excellent for ceramics, plastics, and metals.

Fiber: The fiber varieties are made from so-called seed lasers. They were amplified with the help of special glass fibers. Their wavelengths and intensities can be compared to that of neodymium lasers because of their build. However, they can be more durable and require less maintenance. They are suitable for markings with CNC machines’ help, and the materials they can cut through can include plastics and metals.

Software Used in the Designing Process

The cutters similarly work as an ink-jet printer on your computer. They have particular drivers who work together to convert the computer’s shapes and designs into something physical. They are driven with formats, and the computer ensures that the tools are doing their jobs in a manner specified by the designers.

There are so many packages out there that can help with laser cutting techniques. They can be 2D or 3D, depending on the needs of a specific company. Some of the 2D designs can be made by software like Adobe Illustrator, CorelDRAW, Inkscape, and AutoCAD. For the 3D designs, multiple software packages are available to be specific for each application in the industry. Some of them are Autodesk fusion, Autodesk inventor, Solidworks, and more.

In a cutting operation, the lasers’ head fires at a continuous speed to slice the metals evenly. For the tools to know the parts where to cut, they are often driven along the design piece’s vector paths. Once you have a file that you can send to the cutters, the lines that are just registered on the graphics and hairlines are the ones that will be cut according to specifications. All the other images with thicker lines are going to be rastered.

When the right settings are supplied to the tools, they will do the jobs and score the materials in the way you want them. Vector cutting is usually used for outlines of materials as well as punching holes on metals.

More about Rastering

The rastering process is more challenging than the cutting method. The laser burns off the top layers of the steel or other materials at first. The cuts aim to create grayscale or two-color images with the raster effect.

Rastering may involve setting the lasers’ power to a lower temperature than it would if it’s cutting vectors. Instead of a pulse beam, it will create dots per inch or DPI at selected areas so that the lasers will not cut through.

The correlation of the DPI on the resolution of the images will affect the fineness of the designs. In the best cases, they will appear exactly as they look on the computer. With the use of adjustments on the controls, the lasers’ effects on the materials will also vary.

Many materials that are ideal for rastering can come out clean and clear. You may not expect these with others, though, as the precise results will depend on the materials you’re using and the type of lasers involved. When this is your first time, you may want to do a few experiments before trying the process.

Settings of the Lasers

Before you can start rastering and cutting, you may want to know more about the various settings that you may encounter. Many cutters have four primary settings. These are the speed and power that apply to the vectors. The frequency and the resolution that’s for rastering can all be changed in the dialog box of “Print Properties.”

Remember that the tools are connected to the computer that you’re using. They can always be based on the hardness and thickness of steel and other materials you’re working through. You can set the power and determine the strength of the laser fires.

However, the high-powered ones are only ideal if you are burning a thicker and stronger metal. If not, it can result in a volatile stock that will have darker images and burn more than necessary. Lower-powered ones may not have enough strength, so you need to make adjustments accordingly.

These are just some of the information that you need to know about lasers. There are other settings that you can find in various industries that can help get your work easier. They are usually used in perfecting prototypes before mass producing a machine part.