Modern electronics have come to a point where you can pack immense power in small packages. If we have to give examples, we can surely talk about iPhones. The printed circuit board or PCB of iPhone powers the most popular smartphone in the world. As a hobbyist or engineer, you must have wondered what lies beneath the hood of iPhones.

Today, we are going to take a close look at iPhone circuit board and all the components on it. By the end of this guide, you will become a pro on iPhone PCB and also able to make your own. So let’s dive in without delay!

Section 2: What do You Find in an iPhone Circuit Board?

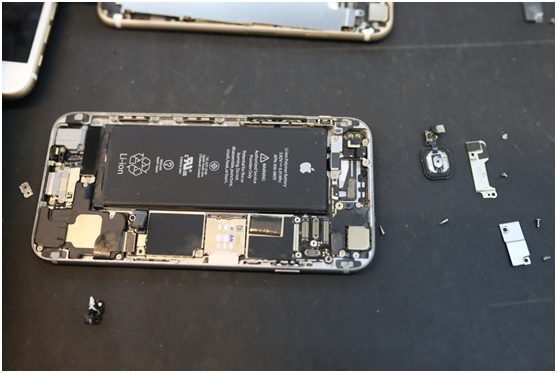

Once you open an iPhone, you will find the following components-

- Battery

- Display

- Printed circuit board

iPhone Circuit Board Components

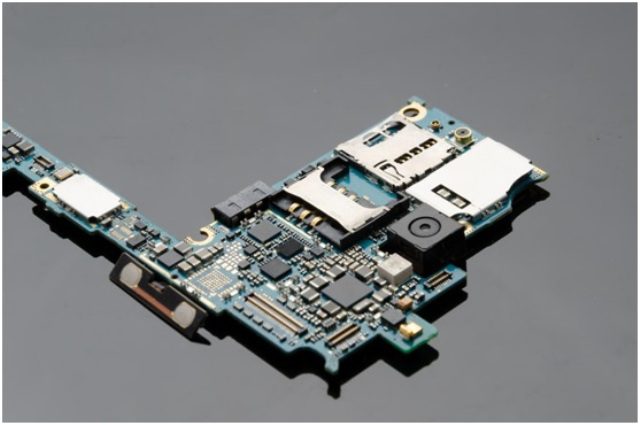

The printed iPhone circuit board is the heart of your iPhone and also known as the logic board. At first glance, you will see many integrated circuits and other tiny components that are fitted together by things like the tape and reel process – check out Pro-Ex’s guide on the tape and reel process to learn more about this.

The battery takes up most of the space, leaving room for the PCB. The front side of the iPhone circuit board contains the central processor. It also occupies a substantial area. You can easily make out the small module that includes the processor and the RAM.

On the left side of the processor, you will find the wireless section. This unit is responsible for sending and receiving radio frequency signals. You will also see a small chip called envelope tracking. It controls the power supply to the wireless section. Next, to it, you will find the LTE multimode baseband chipset.

Here you will also find the inclinometer which tells you the orientation of the screen.

The backside of iPhone circuit board contains many components. It houses the co-processor that works along with the central processor. There is also the flash memory which stores your pictures and music. The backside of iPhone PCB also features the WiFi module.

- The iPhone circuit board contains other critical components like

- Touchscreen controller that reads all the finger swipes

- Power management integrated circuits (PMIC) for voltage control and battery charging

- NFC module for wireless connectivity

- Fuel gauge on the connector cable between battery and circuit board

These are the standard components that you can find on iPhone circuit boards. Some of the elements may vary according to models.

Section 3 : What are the available iPhone board types?

Have you ever thought about what constitutes an iPhone board? The board configuration in the iPhone varies depending on the model we are viewing. The board configuration in the iPhone varies depending on the model we are seeing. However, the iPhone 6 circuit board had a printed circuit board 64-bit architecture that had a motion co-processor built in it. The iPhone 6 got its speed and better graphics from there.

However, with the iPhone X, the circuit board became more advanced. Where many competitor circuit boards have ten layers of copper on the PCB, the iPhone X circuit board has twenty. This higher density translates to having more components in a lesser surface area. The iPhone X circuit board also has two layers of interposers.

Depending on the model of the iPhone we are looking at, we might see the following type of PCB’s or circuit boards.

- Single-layer or single-sided PCB:It has a single layer of the substrate.

- Double-layer PCBs: Itcontains traces on both sides of the board.

- Multi-layer PCBs:Has three or more double-layer PCB.

- Rigid PCBs:This one has a solid substrate material.

- Flexible PCBs:The PCB here has flexible materials like plastic.

- Flex-rigid PCBs:It is a combination of rigid and flexible PCBs.

Section 4 : Take you to know the iPhone board

Wondering what an iPhone circuit board has? Here is a look at all the things that make up an iPhone circuit board.

PCB Board Material

You can choose from a range of materials for your custom circuit board-

- FR-4 uses a glass-reinforced epoxy laminate sheet. The epoxy is resistant to flames and moisture.

- PTFE (Teflon):a type of plastic material used for high-frequency and high-speed projects

- Metal:you can use copper, iron, aluminum, and other materials.

PCB Components

Now let’s explore the various components of PCB-

- Resistors:controls the passing electric current.

- Transistors:responsible for amplifying charge.

- Capacitors:can store electrical energy.

- Diode:controls the direction of the flow.

- Inductors:can store current.

The components of a custom circuit board vary based on your application.

Now let’s head over to PCB design.

Section 5: How much do you know about board design?

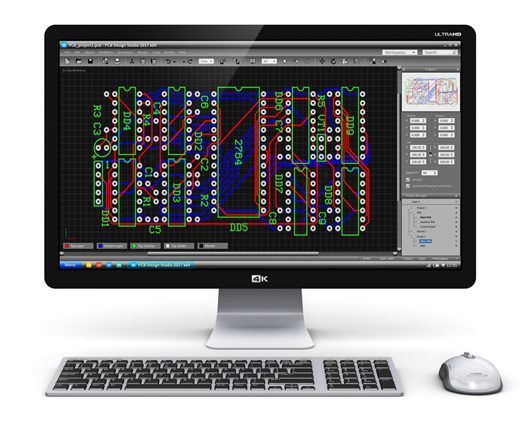

Some people use breadboards to design their custom circuit board. Others also draw their design by hand. But those are not suitable for professional purposes.

Most manufacturers and engineers now use PCB design software. The solutions let you design your custom circuit board in the way you want. You can then print the design and create your custom PCB easily.

PCB Design Guidelines

Keep the following in mind while designing your circuit board-

- Work out the board area you will need

- Decide how many layers you need for your custom PCB

- Determine the mounting technology you will use

- Use the right trace width for your custom circuit board (minimum 0.010”)

- Orient similar components in the same direction for facilitating soldering

- Maintain separate control ground and power ground for each power supply phase

- Consider adding thermal reliefs for high heat applications

- Don’t place components on the solder side of the board

- Determine whether you will use complete planes for earth or power

In the next section, we will discuss some PCB design solutions.

Section 6: Can You Make Your Own iPhone Circuit Board?

You can use any PCB design software to design your custom iPhone circuit board.

- Eagle

Eagle is a popular PCB design software from Autodesk. It is easy to use and can automate the design process. It also comes with intuitive PCB layout tools. The basic version is free while advanced versions cost money.

- Altium Designer

Altium is a professional software for designing custom circuit boards. You can create your PCB layout with tools provided. The solution also features PCB prototyping tools.

You will find ample PCB design solutions from Altium for entry and advanced level users.

- PADS (PowerPC)

The tool is straightforward and easy to learn. Small companies will significantly benefit from using PADS for the PCB design. You can create high-quality designs using smart devices with perfection. PADS PCB widely used in the industry.

- TinyCAD

TinyCAD is a free tool to create circuit designs. You can take advantage of the symbol library to start designing without delay. The tool allows you to save your plans as png or Word documents. You can also take a printout if needed.

- EasyEDA

EasyEDA is a free cloud-based PCB design tool. You can use your browser to design PCBs and create layouts.

Now a few words on the PCB layout.

Section 7: Custom Help to Make Your Own Circuit Board Layout

Did you know that you can reverse engineer to design a similar circuit board? You can use it to create schematics of existing PCBs for repairs and replacement.

With us, you can ensure that you have all the help you need to design a circuit board you like. Our experts can help you develop one. We will take into account all your needs when creating it. Yes, it is going to be similar to an iPhone circuit board, complete with great features.

You do not have to worry about any problems we encountered as we have done so for many years. More, should you have bulk requirements, give us a call or email, and we will love to provide you with special pricing. That sounds great.

Conclusion

Creating custom circuit boards are not painful. You can easily design your custom PCB using PCB design software. Or, we can help you do it too, should you have business needs.

We are a reliable manufacturer and will produce quality PCBs matching your exact specifications. If you are unsure about how to go about, you can also contact us. We can help you out with professional guidance. We can also create custom circuit boards with the highest standards and quality checks. Make the custom PCB-making process as an easy one.

About Author:-

I am Abby, from China. I am pleased to meet everyone; I hope everyone likes this article. I am an electronics enthusiast and have been working on PCBs. I hope to share more beautiful things with everyone! Thank you!