Much of the comforts we enjoy today have become possible through the applied science behind electronics. From the moment you wake up, count the times you’ve relied on electronics to do your daily tasks such as communication, watching news, doing reports for your job, and more. We’re so saturated with the countless products of electronics that we don’t notice them anymore.

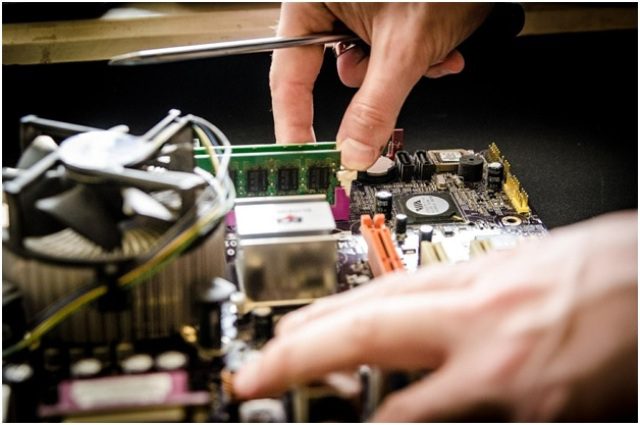

If you specialize in this profession, you know for sure how complicated it is to build a good electronic device. It’s a meticulous handwork with lots of squinting. You may have heard some technicians say, “It’s not a trade for someone who doesn’t have a 20/20 vision”. And that’s indeed a good point.

More than that though, electronic engineers and technicians are more meticulous with the components they use. Obviously, good electronic spare parts are the building blocks of a device that performs efficiently. Thus, it is important to choose suppliers carefully, making sure the components you receive from them are of topnotch quality.

What is Surface Mount Technology Anyway?

It was in the 1960s when surface mount technology was first invented but it was only in the 1980s since it became more popularly used. Since the late 1990s up to this day, many high-tech electronic devices are already being assembled through it. Read more about that here.

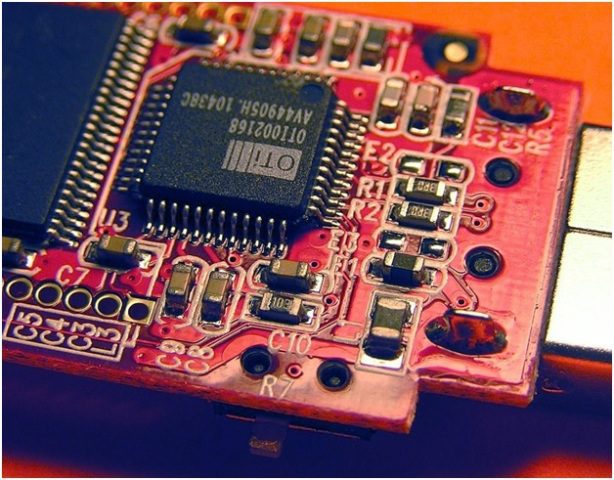

But what is surface mount technology a.k.a. SMT? In summary, it is a process of creating electronic circuits by placing or installing the components directly on the surface of a printed circuit board. It is entirely the opposite of its counterpart called the through-hole technology which as the name suggests, is the process of inserting components with wire leads into the holes of the board.

SMT has almost replaced this traditional counterpart because of its many advantages. First of all, unlike the through-hole technology, it is less time-consuming. Thus, the device is easier to assemble. It is also less costly as compared to the other conventional process yet provides better quality and efficiency under shock and vibration. The page Surface Mounted Devices discusses more advantages and related facts about SMT.

That doesn’t mean though that we have already totally ditched the through-hole technology. We still need it in situations where SMT is not applicable. Large transformers are one example in which the through-hole technology is the best method.

Choosing the Right Suppliers

Sometimes, the most challenging part of a project is not the production itself, rather, it’s the search for the right components and the right suppliers who can provide them. It’s more challenging back then. But, now, with the help of the internet, some good ones are just one click away.

You can also ask your colleagues and other family members who are adept with this profession if they know some reputable suppliers or manufacturers. In addition to this, you can attend trade shows. These events are great opportunities to meet different companies who manufacture electronic spare parts as well as experienced professionals who can share valuable insights and pieces of advice with you. It will be the perfect time to network with them.

How can you choose among them? First, get to know the company’s stability. Have they been managing this kind of business for a long time? What do their customers say about their products? What proofs can they show that the components they produce are high-quality? It is also important to know the minimum number of parts you can order from them.

You need to find honest answers to these questions. One way to do so is as simple as talking to their previous clients. If they’re not afraid to provide references, it means they’re confident about the kind of work they do. This article explains more tips on how you can find suppliers and work with them: https://www.entrepreneur.com/article/66028

Also, ask about guarantees. What if the product comes defective? What’s their policy on this? If they implement “no return policy”, you better move on and find someone else who prioritize their customers’ needs.

Are you excited for your next electronics project? Determine all the components you need. Then, find and choose the people you’ll be working with wisely.