Preventive maintenance can make all the difference to your business if applied correctly. Here, you will have to plan months or even years ahead. That being said, a successful preventive maintenance strategy will give you peace of mind since now you know that your best assets are protected.

Preventive maintenance is worth it even though it is time-consuming as it minimizes the number of unexpected equipment downtime and maximizes the life expectancy of assets. But before you start implementing this strategy, take a look at the following article where we discuss a few mistakes that you need to avoid in preventive maintenance plans.

Not involving correct team members

You need to include and get approval from the personnel in charge of managing the change as strong support from the upper management will be a solid indication to the staff that will be easy to accept, especially if it is followed by written procedures. If this is not done, the employees may not take the plan seriously as they should.

Hence, it is imperative that you involve everyone in the process and that everyone knows hows the processes will unfold and what their responsibilities are. For example, you may need to ask for an extra budget to purchase CMMS. If the upper management were not aware of this or if you didn’t get their approval, you may have to stop the process before it begins.

Failure to create written procedures

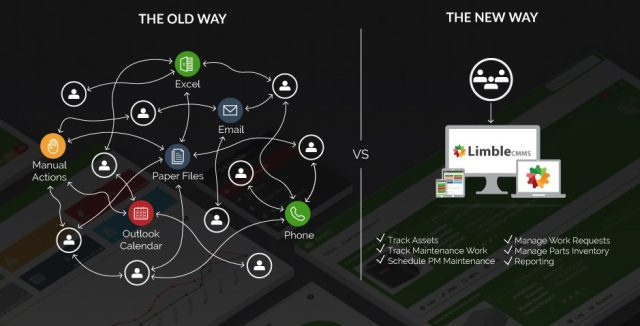

If you do not create proper written procedures when you transition from a reactive maintenance strategy to preventive, it will take some time for old habits to die. There is a huge change in workflow here which will need some time to get used to.

Working in a reactive maintenance environment may be seen in poor record keeping, multiple spreadsheets and outdated or lack of written procedures for maintaining the assets of the company. Having written records help eliminate mistakes and oversights. Simply writing is not enough, you have to ensure that the technicians follow these written procedures.

Inadequate equipment inventory

You have to decide which equipment will be added to the plan and which will be left behind. If the asset is costly to repair and would cause major problems if it goes down then it should be the first one added to the plan. If you have some old equipment that you are planning to replace as soon as it malfunctions, you don’t have to add it to the plan. The inventory should involve information like model, make and serial number as well as the areas of the equipment that need attention regularly.

Lack of staff training

The staff has to be trained properly to ensure the efficient running of the plan and to reduce the cost of operations. A properly trained staff will ensure that your preventive maintenance strategy is on track. If the staff in charge of the plan is not aware of the critical assets and their working condition, you will end up doing a lot of corrective maintenance.

Setting the plan and forgetting it

You need to constantly oversee the plan and tweak it whenever and wherever necessary. You have to track its effectiveness and ensure that the assets are maintained regularly. Any redundancies or unnecessary steps should be eliminated as you don’t want that. Also, make sure that everyone follows the plan throughout.

Also Read:- Why Investing in Cloud Technology Reduces Risks for Your Business