3D printers have gained popularity in the past few years as one of the most fascinating inventions made available on the market. The worldwide 3D printing industry is expected to exceed $21B in worldwide revenue by 2020. The 3D printing industry is undoubtedly promising, and it shows no sign of slowing down.

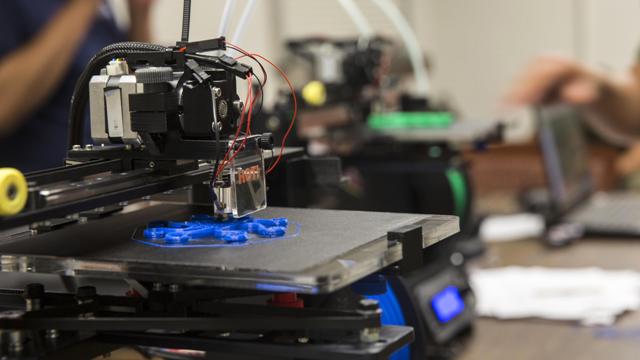

3D printing is the process of creating three dimensional solid objects based on a digital file design. The creation of a 3D printed object

is achieved by laying down raw materials in successive layers until the object is fully printed. The digital file guide lets the printer know when the design is finished.

While 3D printers started as an unusual innovation, its new levels of affordability and increased market presence have created a huge fan base. More and more manufacturers are offering 3D printers for purchase to the public at price points that are within reach for many at home users.

Many businesses are using 3D printing as a way to print parts they may have previously had to purchase from a vendor, and technology is even finding ways to make use of 3D printers in other areas such as healthcare.

3D printing has also been applied in other industries such as education, rapid prototyping, replicating ancient artifacts in archaeology, reconstructing fossils in paleontology, and reconstructing heavily damaged evidence acquired from crime scene investigations. Some companies have also used 3D printers to create more 3D printers.

There’s a lot you can do with a 3D printer, and your options are only increasing as the market grows. If you’ve ever wondered what you can do with a 3D printer or what a 3D printer is capable of on a larger scale, keep on reading. Here are some things you may not have known were possible using 3D printing technology.

Aviation

The aviation industry utilizes 3D printing in a wide variety of ways. Boeing was one of the first companies to explore the possibilities 3D printing offered to their industry. Back in 2015, it was estimated that Boeing had more than 20,000 3D printed parts implemented on their airplanes.

Boeing has also advanced to utilizing more advanced options of 3D printing like printing with newer types of materials for more durable or sensitive airplane parts. The 787 uses a large variety of printed titanium parts, saving the company 2 – 3 million dollars per plane.

Aerospace

From materials to concept printers, the aerospace industry is using 3D printers in ways that are entirely unique to their needs and fields of practice. 3D printing is being used in the aerospace industry to create high-quality functional prototypes for training purposes. They’ve replaced small things like brackets and door handles to save a lot of money.

They’re also creating “surrogate” parts to more effectively manufacture products that are exclusive to the aerospace industry. Prior to the ability to test out how parts would fit and work together by printing these surrogates the creation of a new design for use in an aerospace application was much more costly. Because of 3D printing, they are now able to test how things will work in a low-risk way before committing to a final build.

Construction

Without a doubt, the construction industry has a broad scope making it a great industry to implement the use of 3D printers. Construction company Apis Cor is producing fascinating results in using 3D printers in the industry. The company claims that it can use a 3D printer to finish an entire house within 24 hours.

Because of their innovative uses of 3D printing Apis Cor often lends out its machinery to various other firms. Their success has encouraged more and more construction companies to look for new exciting ways to use 3D printers to build even bigger projects like larger scale buildings.

A project by Shanghai-based construction company WinSun uses recyclable materials to print houses for $4,800 per unit. In their business model, all the parts are printed separately and assembled later on.

This 3D printing initiative, has China offering brand new homes to its citizens with more ease than it ever has before. Since some 3D printed parts can be made out of recycled materials China is also experiencing some environmental benefits utilizing this new method of building homes.

Architecture

Architecture as an industry was one of the earliest adopters of 3D printing technology. Architects use 3D printers to present their works in a systematic and detailed manner. They can create a physical scale model quickly and efficiently.

The ability to print a 3D model of their design concept instead of building a small scale version out of materials themselves has given architects many options they didn’t have before. Clients are seeing their building concepts presented more clearly and the cost of creating these models has decreased significantly.

Consumer products

When it comes to consumer products the use of 3D printers to create prototypes is a big part of how this industry is using this new technology. The ability to print a prototype of an idea before creating a large scale order is invaluable to many product designers.

Some of the common consumer products where 3D printers are used include accessories, jewelry, lighting fixtures, and furniture.

One of the most popular furniture company utilizing 3D printers is Steelcase. Steelcase has invested a lot of time and money into discovering new techniques to print furniture parts that are durable and still stylish. Because of Steelcase’s success, other companies have started to see what 3D printing can do to streamline their own design processes.

As larger-scale 3D printers are becoming more available the applications for printing consumer products is scaling up too. Companies are already looking at how they might be able to produce even larger furniture (think large office furniture) or other scalable products at a more affordable price for both the company and the consumer.

Food

3D printing made its way into the food industry a long time ago. There are restaurants like Food Ink and Melisse that attract customers from all over the world because of their highly unique ways of creating foods using 3D printing techniques.

Consumers can now order shape-changing or transparent pasta and there are even pancake printers you can buy to use in your own home. Even NASA is getting in on the action and has used 3D printing to print a pizza while in space.

Healthcare

The entire healthcare industry has a lot to be thankful for when it comes to 3D printers. The outlook for medical and dental uses of 3D printing is evolving at an extremely rapid pace. Medical and dental specialists are using 3D printers in more advanced ways every day.

3D printers are being used to make simple things like bite splints, night guards, and retainers as well as advanced things like bioprinting. Bioprinting involves a 3D printing technology that actually creates living cells in a laboratory environment. The potential uses for 3D printing technology within the medical field are unlimited and very exciting.

3D printing and all the possible applications it currently has is really just scraping the surface of where this technology will be able to go. As industries test newer and more innovative ideas 3D printing will grow along with them.

The potential for 3D printing technology to change the way we interact with the world is already happening every day. What started out as something with small scale possible applications has become an entirely new way to create everything from basic necessities to highly complicated medical devices. It’s impossible to know where things will go from here but whatever ends up happening, it’s sure to be exciting.